Cuisipro Folding Grater

Browne & Co. is a Canadian company that has been making innovative culinary tools for over 30 years. They launched the Cuisipro brand in 1998 and have continued to follow founder Peter Brown’s original vision in relentlessly striving for innovation and pushing the boundaries of what it means to be a home chef. Despite Cuisipro employing a stellar team of designers in-house, we were so happy to have the opportunity to generate some fresh ideas within their grater product line. We were challenged to think outside the box and to come up with meaningful product designs that consumers would love to add to their kitchen tool collection.

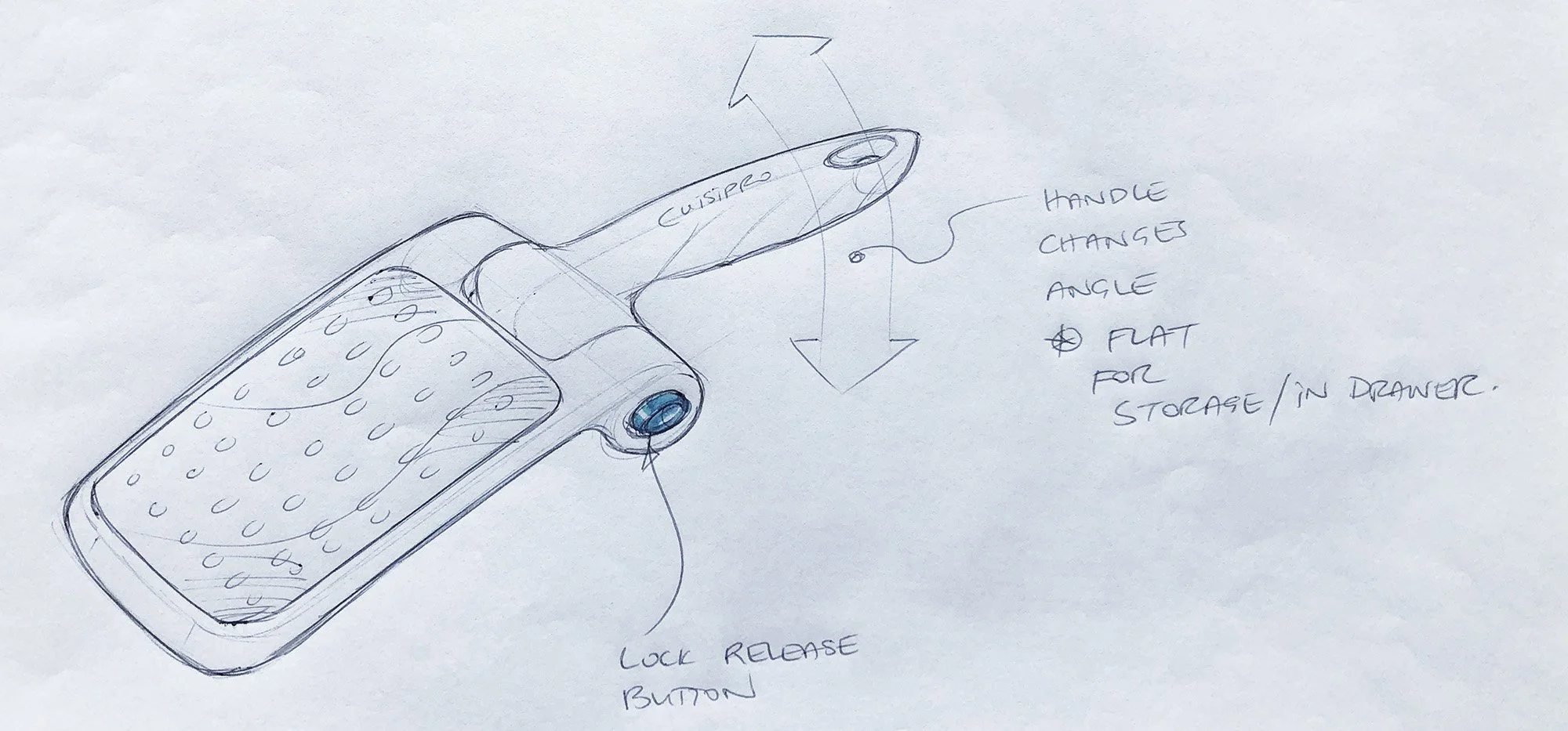

The design process began with familiarizing ourselves with the Cuisipro product line, as well as with competitive market analysis. We tested grater samples, making observations on their strengths and weaknesses. In parallel, we started brainstorming and mind-mapping; these thoughts included feature ideas, pain points, use-case, environmental or material based observations. Some key problems surfaced from our research and analysis; existing graters take up a lot of space in the drawer, the ergonomics of hand-held graters is limited and can be challenging in some use-cases and the current graters in the Cuisipro are not stable while grating with rubber foot placed on counter/cutting board. During ideation, we explored folding as a solution to both improve ergonomic flexibility, and to reduce space taken up when not in use.

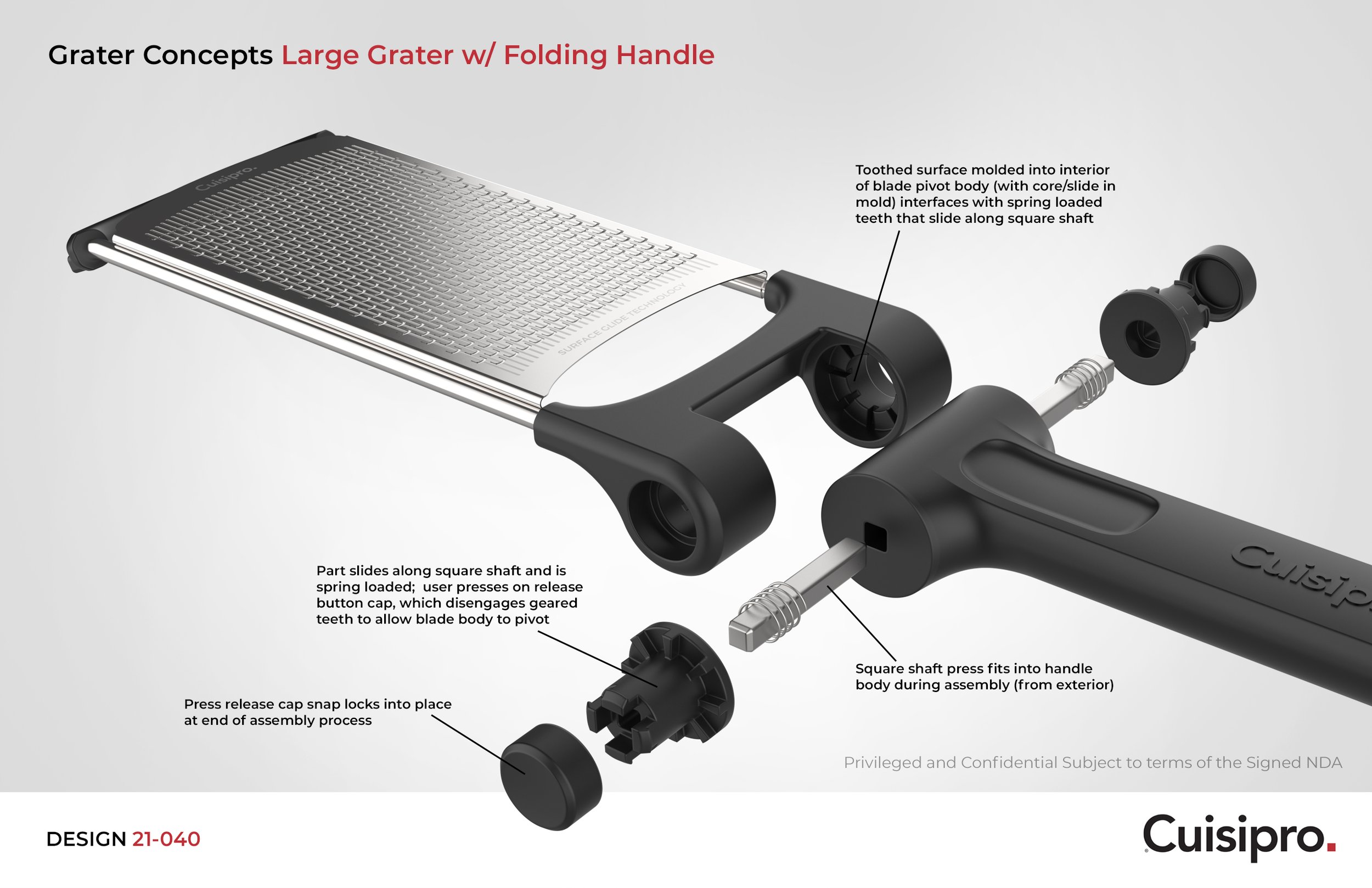

Referencing the design of the existing hand-held graters from Cuisipro, we began developing the design in SolidWorks. We wanted to ensure that some key details were resolved such as how the blade would merge with plastic body, and how the hinging mechanism would function, while considering whether the design could be dishwasher safe for easy cleaning. The initial CAD design included a resolved hinge and press button release mechanism blade with over-molded plastic frame, co-injected rubber bowl retention feature, stabilizing feet, and ergonomic grip handle. Hinge mechanism was designed with indexing angles so that product will securely hold at chosen angle during use.

We shared the initial design with the client for review, and held an internal peer review. This included 3D printing the design for ergonomic assessment, where we had as many people try it out with minimal instruction to observe how they handled and intuitively used the grater prototype. We observed that even those completely unfamiliar with the project understood to use the side push buttons to unlock the pivot. We also observed that users seemed to struggle using the grip with its drafted shape and width. After reviewing our own findings and the Cuisipro team’s comments, we started tweaking our 3D design with a major redesign of the handle to optimize ergonomics. Once design updates were addressed, we executed simplified design boards and CMF for Cuisipro’s engineers and production team to review in detail to fully evaluate materials, mechanics and production costs.

After review by Cuisipro’s factory engineers, it became clear that the molded frame around the grater blade would be too costly to mold and create a high scrap percentage. We made the suggestion that if we went back to a wire frame construction like their current full size graters, we could modify the joint design to co-inject over the wire and create a robust connection between the parts. This design revision finalized the design and it was handed off to enter their product launch queue. The design work for the product was conducted in Fall of 2021 and launched Summer 2024.